Project Overview

This fabric centers on innovative integration: the outer layer uses perforated lustrous nylon filaments as base material while the inner layer is made of mugwort processed by nano-level grinding and high-temperature spinning, blended with composite powders of volcanic rock and aerogel to create a composite fabric that combines rich texture, comfort, durability, health benefits, and thermal performance, meeting consumers’ demands for comfort, quality, health, and functionality.

Organisation

Hangzhou Ouchao Trading Co., Ltd.

Team

ASK JUNIOR

Project Brief

In today’s increasingly competitive functional apparel market, consumer expectations for fabric have evolved from single-performance to multi-dimensional features encompassing texture, functionality, health benefits, and sustainability.

This fabric features perforated lustrous nylon filaments as the outer layer, with a composite inner layer made of mugwort, volcanic rock, and aerogel powder, achieving enhanced functional performance. With premium craftsmanship and eco-friendly design, this fabric’s core competitive edge lies in its high-end texture, functional health features, and sustainable process and materials, making it perfect for outdoor sports, daily commuting, and children’s wear.

Project Innovation/Need

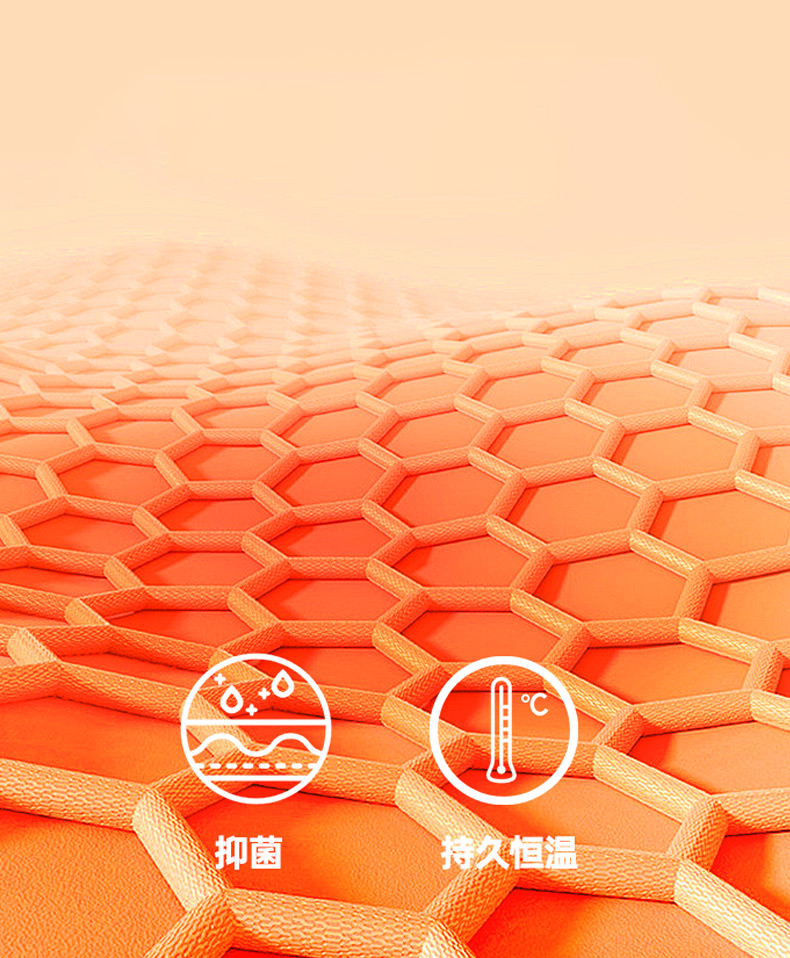

Health and Comfort: The fabric’s inner layer contains mugwort fibres rich in natural antibacterial compounds and featuring anti-mite properties, helping to reduce odours and the risk of skin allergies. Complemented by zinc’s long-lasting antibacterial effect, the fabric forms a dual protective barrier. Additionally, the fabric releases negative ions, which improve air quality, alleviate fatigue, and enhance comfort during extended wear.

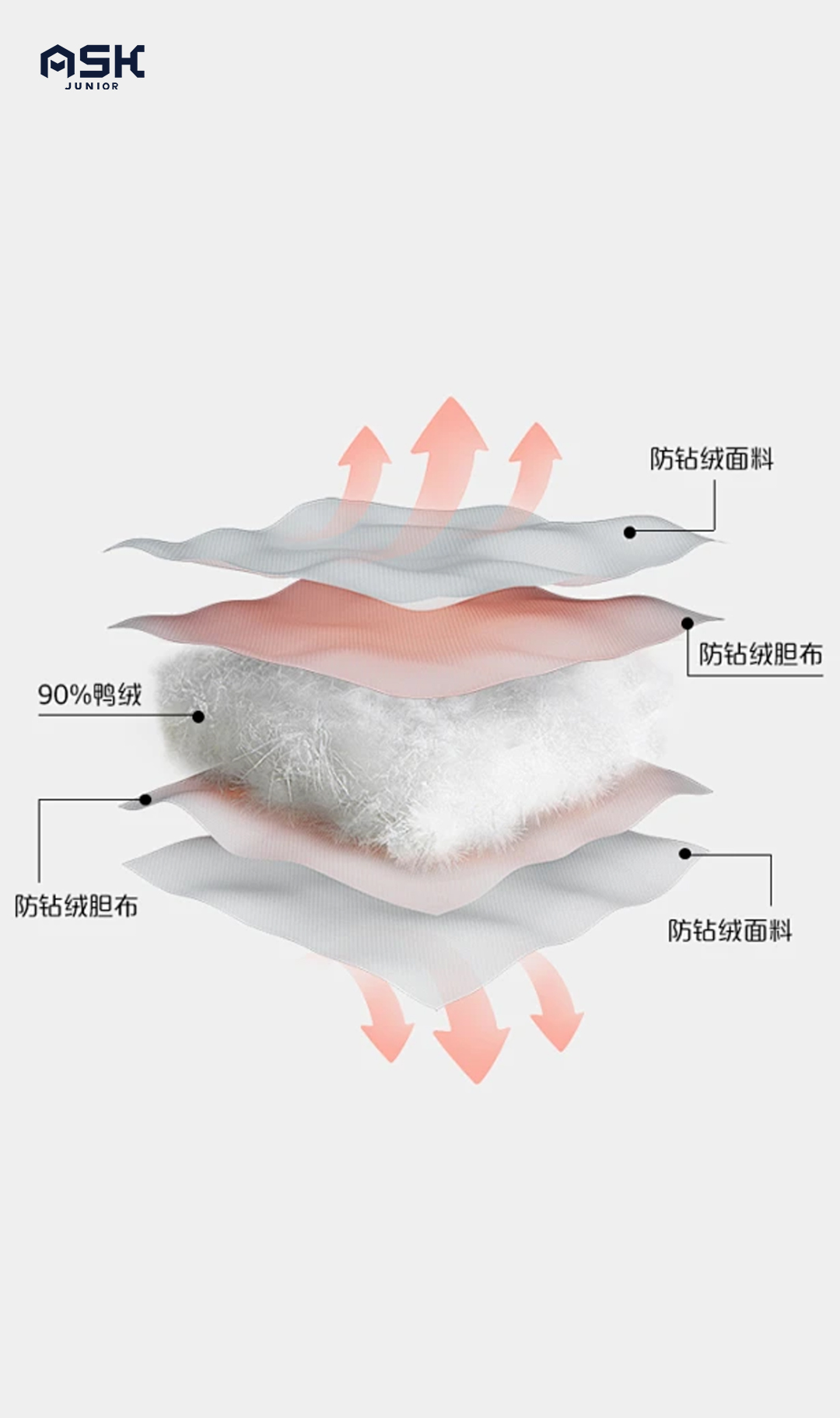

Advanced Thermal Performance: Volcanic rock and aerogel deliver lightweight insulation through their honeycomb porous structure. Coupled with the 4C groove yarn design that increases loft, internal thermal circulation is improved for long-lasting warmth. Moreover, the fabric emits far-infrared radiation to promote subcutaneous blood circulation and alleviate joint chill, particularly suitable for the elderly and individuals with a cold constitution.

High-Performance Protection and Abrasion-Resistance: The outer layer is made of round-section nylon filaments with level-4 PFC-free water resistance. Its unique perforated structure significantly enhances breathability, making it suitable for high-intensity activities or prolonged wear. It also retains nylon’s high strength and abrasion resistance, adapting to complex outdoor environments.

Design Challenge

Inner Layer Design: One major challenge was how to evenly incorporate composite powders of volcanic rock and aerogel into the mugwort fibers without compromising the fabric’s inherent properties. Through extensive experimentation and careful refinement of process parameters, the design team developed specialized incorporation methods and mixing techniques that ensured an even distribution of the composite powders. Comprehensive testing further confirmed that the fabric’s breathability, softness, and overall performance remained fully intact.

Outer Layer Design: Another challenge lies in achieving multiple functions without compromising the fabric’s texture, appearance, and style. By refining the weaving and dyeing techniques of perforated lustrous nylon filaments, the fabric achieves a harmony of performance and style—retaining vibrant colors and a refined sheen while delivering all its functional benefits.

Sustainability

Sustainable Materials: Sourced from widely available, naturally renewable mugwort, the fabric reduces reliance on non-renewable resources.

Green Process: Dyed with Class A infant-safe dyes certified by international environmental standards, the fabric is free of fluorescent agents and formaldehyde, ensuring safety while being kinder to the environment.

High-End Equipment: The production process utilises Kyoritsu air-jet looms from Japan and calenders imported from Germany, which significantly enhance production efficiency and reduce energy consumption. Compared to conventional equipment, these high-end machines reduce energy usage by up to 40%, lower defect rates, and maximise resource utilisation.

Fashion - Textiles & Materials

Exemplary textiles and materials that have low consumed energy, low water use and low waste - aka Eco-Textiles. Over the coming 3 years we'll be furthering our Eco-Textile standards - be part of the evolving standard by nominating your innovations.

More Details