Key Dates

Image Credit : Peter Clarke

Project Commissioner

North Western Project Alliance

Project Creator

Project Overview

Genton’s design for Pakenham Station redefines transport infrastructure as a civic landmark, blending cutting-edge digital fabrication with urban renewal. Located in Melbourne’s southeast, the elevated station eliminates three level crossings while introducing over 20,000 square metres of new public space, transforming a once-divided suburb into a thriving, interconnected precinct.

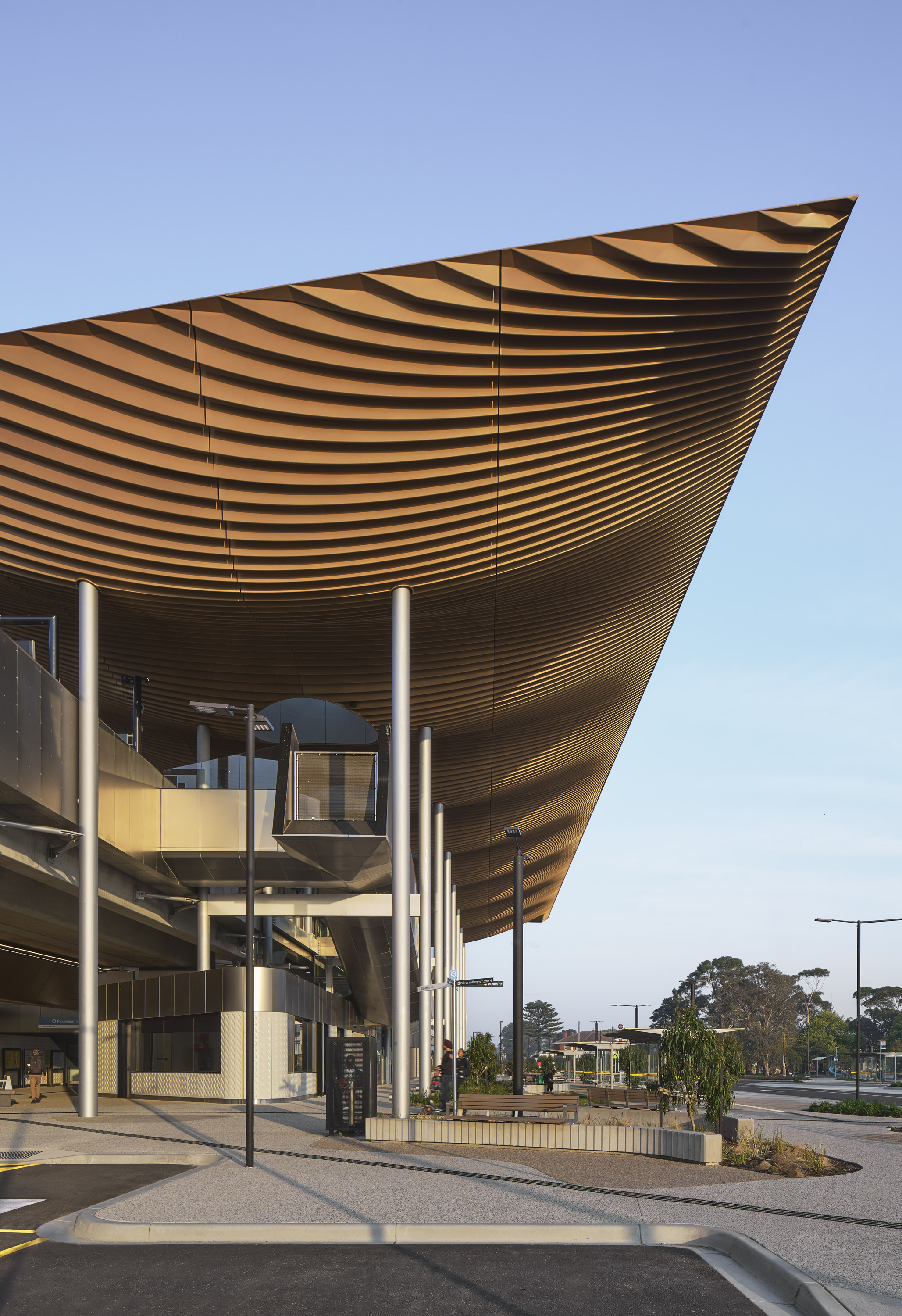

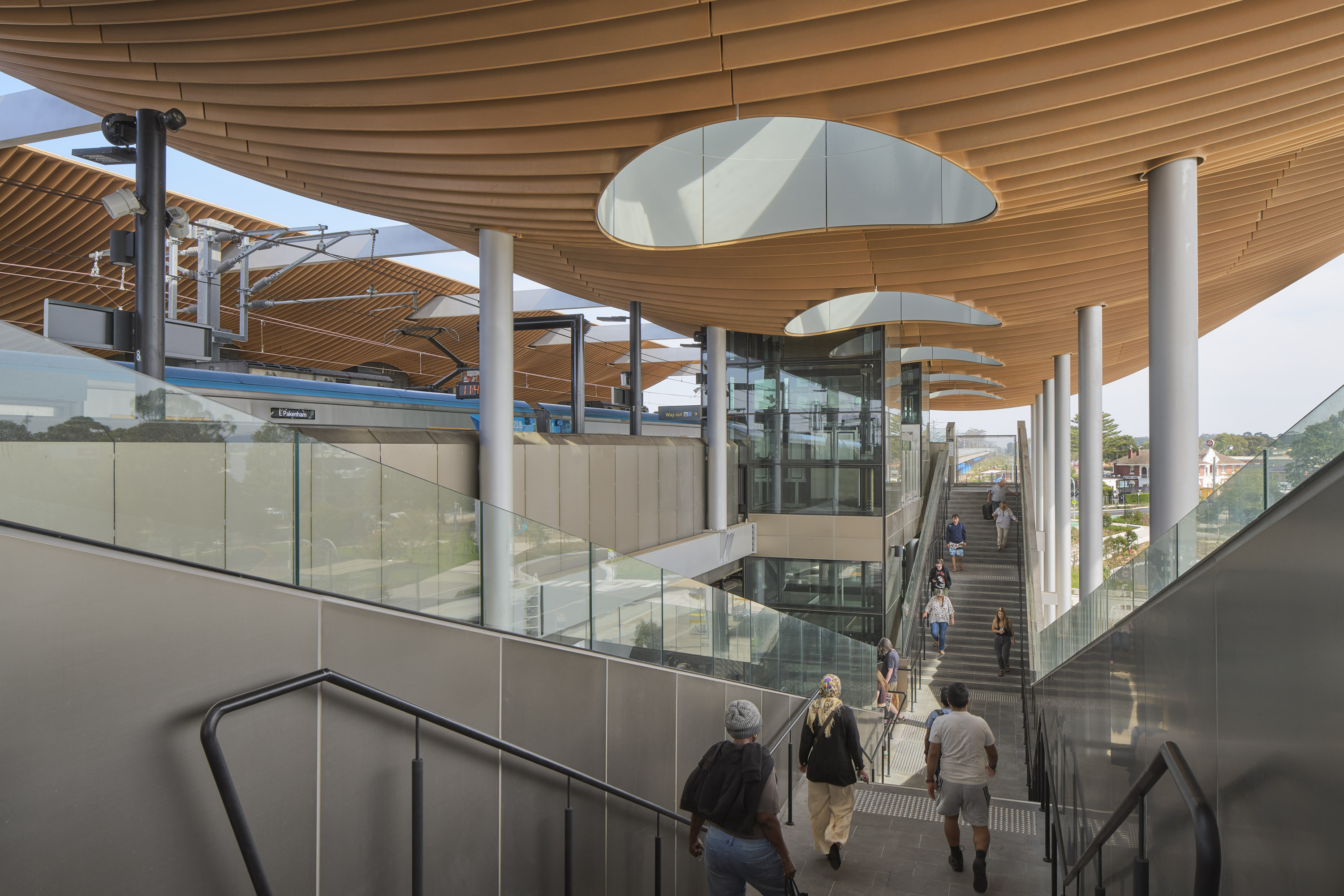

At the heart of the design is an expansive, wave-like canopy—crafted using digitally fabricated reinforced thermoset—which eliminates the need for excessive steel and aluminium, reducing embodied carbon. The station’s radical openness removes traditional walls, ensuring unobstructed views, enhanced safety, and seamless integration with the surrounding landscape.

Beyond functionality, Pakenham Station celebrates Indigenous co-design, with architectural elements referencing local cultural narra-tives, such as the wings of Bunjil, the wedge-tailed eagle. The Bunjil feather pattern is engraved into the GRC, creating a tangible, tactile experience that allows people to physically interact with the Indige-nous storytelling embedded into the station.

A 2km long civil retaining wall between East Pakenham & Pakenham Station creates A linear journey along the Shared Use Path. The eel trap motif references the traditional land use practices of the Bunu-rong people, showcasing how First Nations communities historically engaged with the landscape.

The project’s emphasis on transparency, sustainability, and public connectivity positions it as a benchmark for future rail infrastructure, proving that transport hubs can be both highly functional and deeply embedded in the cultural and environmental fabric of their communities.

Team

Marc Debney, Jamie McCutcheon, Steven Toia, Sehar Abidi, Sam Blake, Chern Wong

Project Brief

The new Pakenham Station challenges conventional station design to create a striking, sculptural transport hub that redefines the commuter experience. Surrounded by open space and distant from residential neighbours, the station is conceived as a civic landmark—a transparent, elevated structure crowned by dramatic bronze canopies and a flowing soffit inspired by the rolling hills of Gippsland.

This is not a typical suburban station. Pakenham is a gateway: to Gippsland, to Melbourne, to the future of regional transit. The removal of traditional facades allows seamless visual connectivity, transforming the station into a welcoming threshold. A double row of columns frames the public realm, giving the station a formal, airport-like civic presence. As passengers move from ground to platform, they experience curated views to the north and south, turning the commute into a scenic journey.

The design prioritises connection—between town and platform, between people and place. With three level crossings removed, new public realm added, and improved links for pedestrians, cyclists, and drivers, the station integrates seamlessly into the heart of Pakenham. It brings with it a renewed identity for the town centre, underpinned by improved access, new bus interchanges, 450 car spaces, and cycling infrastructure.

Pakenham Station establishes a bold new station typology for Melbourne—one that is civic, open, and deeply rooted in place.

Project Innovation/Need

Pakenham Station represents a major breakthrough in 3D digital manufacturing for rail infrastructure, setting a new precedent for precision, efficiency, and sustainability in construction. Genton’s approach eliminates traditional steel-heavy fabrication in favour of an advanced digital-first design-to-construction workflow, dramatically reducing material waste and carbon footprint.

The station’s wave-like canopy—its most striking architectural feature—was designed, modelled, and fabricated using a fully digital process. The journey began with hand sketches, which were translated into parametric models using Rhino and Revit, ensuring exacting precision while allowing rapid refinement. Through advanced computer-controlled digital fabrication, the final design was realised in reinforced thermoset, a lightweight, high-strength alternative to steel.

Unlike conventional construction, where prototyping and material waste are unavoidable, Genton’s process allowed for millimetre-accurate component production from a single digital model. This reduced raw material consumption, eliminated excess prototypes, and minimised CO₂ emissions, proving that large-scale transport infrastructure can be delivered with both architectural ambition and environmental responsibility.

Additionally, dematerialisation strategies were embedded in the design. By using reinforced thermoset instead of aluminium cladding, the station drastically reduced its reliance on energy-intensive materials, further lowering its environmental impact. The prefabricated components were produced off-site, improving quality control and allowing for rapid, low-disruption installation in a live rail environment.

This pioneering use of 3D digital manufacturing in rail construction sets Pakenham Station apart. It proves that digital fabrication isn’t just for experimental projects—it’s the future of high-performance, sustainable infrastructure.

Design Challenge

Designing Pakenham Station presented a unique set of challenges, from material innovation to ensuring seamless integration within an active rail corridor. The most ambitious aspect of the project was rethinking traditional station enclosures—removing walls to create a fully open, transparent transport hub. This radical departure required a new approach to structural design, weather protection, and material efficiency.

Wind exposure and weather protection became critical considerations in this open-air design. Without walls, passenger comfort and safety needed to be addressed through careful roof overhangs, skylight positioning, and wind barriers. The canopy’s precise geometry was optimised through digital modelling in Rhino and Revit, ensuring a balance between protection, ventilation, and natural light.

The key challenge was achieving a durable, lightweight, and sustainable canopy structure without relying on conventional steel-heavy construction. Steel and aluminium, while standard in rail infrastructure, come with high embodied carbon and significant material waste. Genton overcame this by adopting reinforced thermoset, a digitally fabricated alternative that provides structural strength while significantly reducing weight and environmental impact.

Additionally, working within a live rail environment meant tight construction schedules and minimal margin for error. The use of computer-controlled fabrication allowed for millimetre-perfect components, ensuring rapid assembly on-site and reducing disruptions to commuters.

Pakenham Station’s ‘naked’ design pushed the boundaries of rail architecture, proving that high-performance, sustainable infrastructure can be both innovative and practical.

Pakenham Station’s ‘naked’ design pushed the boundaries of rail architecture, proving that high-performance, sustainable infrastructure can be both innovative and practical.

Sustainability

Pakenham Station redefines sustainable rail infrastructure through advanced digital fabrication, material innovation, and environmental efficiency. By prioritising dematerialisation and digital-first construction methods, Genton significantly reduced the project’s carbon footprint and material waste while enhancing long-term resilience.

A key sustainability achievement was the replacement of traditional steel and aluminium with reinforced thermoset, a lightweight, high-strength material with a lower embodied carbon footprint. Unlike conventional methods that require excessive raw materials and energy-intensive production, digital fabrication allowed for precise, waste-free component manufacturing, minimising resource consumption.

The station’s ‘naked’ design, eliminating unnecessary walls, further reduced material use while enhancing natural ventilation and daylight penetration, lowering reliance on artificial lighting and mechanical cooling. Additionally, the prefabricated elements were manufactured off-site, reducing on-site waste, energy use, and disruptions to the local environment.

Beyond the station, the project delivers 20,000 square metres of newly landscaped open space, transforming former rail corridors into public parks, fitness circuits, and cycle paths, fostering social sustainability and long-term community wellbeing.

By embracing digital manufacturing, material efficiency, and low-carbon materials, Pakenham Station sets a new benchmark for responsible, high-performance transport infrastructure.

Architecture - Public and Institutional

This award celebrates the design process and product of planning, designing and constructing form, space and ambience that reflect functional, technical, social, and aesthetic considerations. Consideration given for material selection, technology, light and shadow.

More Details