Project Overview

DELIASOPIN has designed a groundbreaking bedding solution for modern lifestyles and diverse home scenarios—the Piano Key Bed. As its name suggests, with a gentle touch on the pneumatic switch located on one side of the bed, the bed board gracefully lifts like piano keys, revealing a hidden storage space underneath. This innovative design transforms the typically underutilised space beneath the bed into a functional second layer of living interface, maximising the spatial value of small living spaces.

Project Commissioner

Project Creator

Project Brief

The Piano Key Bed adheres to a minimalist design philosophy, eschewing any superfluous or intricate decorative elements on the headboard, footboard, or side frames. Its sleek, elegant, and standardised form allows it to seamlessly integrate into any bedroom style, regardless of room size. It consistently delivers maximum functional efficiency with minimal spatial footprint, respecting the value of every inch of bedroom space.

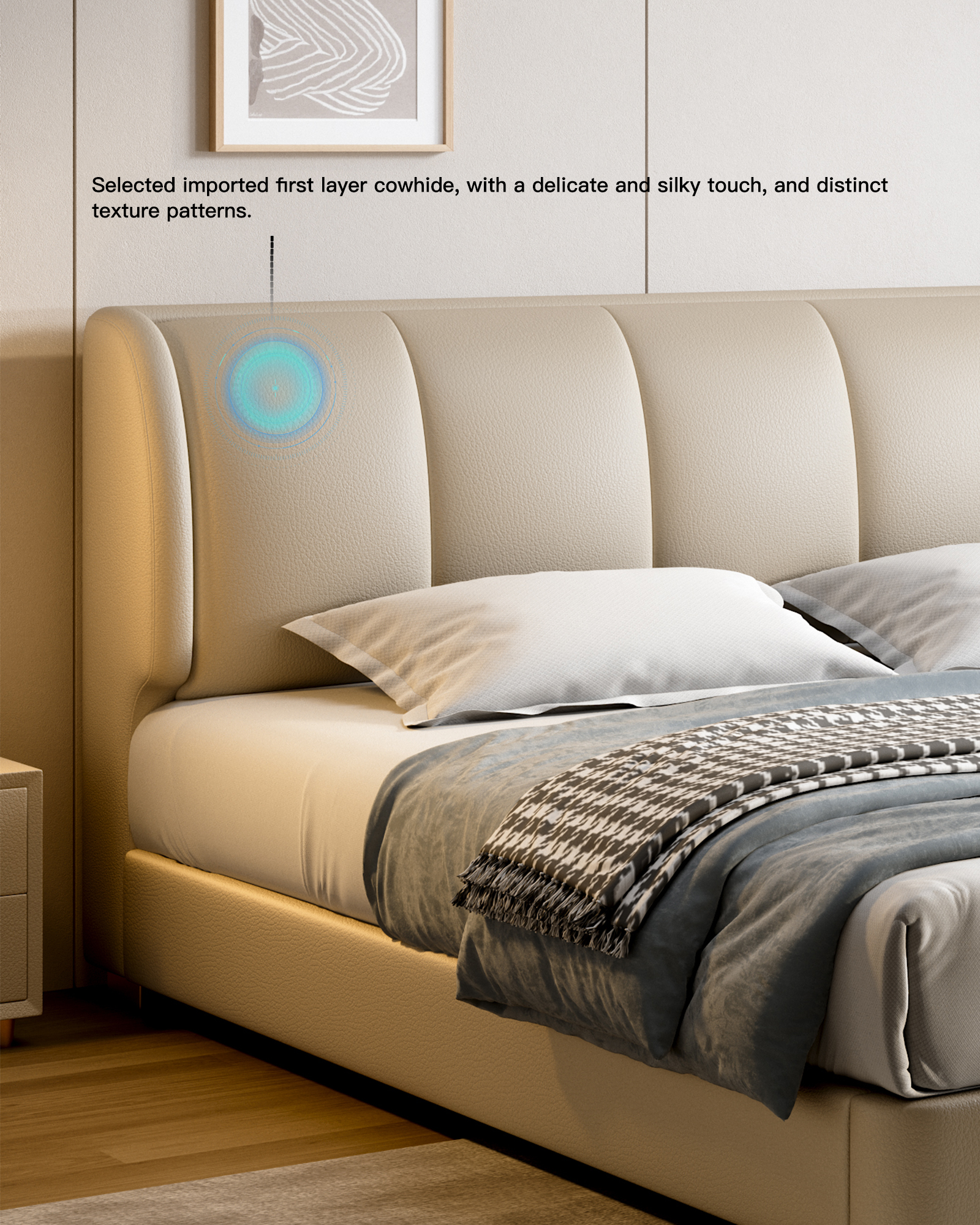

All surfaces of the bed that come into direct contact with the body are covered with a single piece of natural leather, including the headboard, footboard, and side frames, eliminating uneven texture or potential wear risks associated with stitched seams. The leather’s inherent breathability and moderate elasticity effectively mitigate wrinkles or sagging caused by pressure deformation during long-term use.

The headboard cushion is designed with a full, three-dimensional shape, filled with high-density bamboo charcoal antibacterial sponge. This material naturally eliminates odour buildup from frequent leaning, contributes to improving the local air environment, and provides antibacterial properties to reduce the risk of bacterial growth.

Project Innovation/Need

Building on the pneumatic lifting mechanism, DELIASOPIN offers several distinct styles to cater to varied user preferences. The standard model features a piano-key-like diagonal lift, ideal for users who value a sense of ritual and spatial openness. Additionally, a horizontal sliding lift model allows the bed board to glide out levelly without tilting, making it easier to access and store larger items such as bedding, pillows, or seasonal goods.

To address diverse storage needs, DELIASOPIN has meticulously planned the under-bed storage space. Options include dedicated drawer units (e.g., double-layered partitioned drawers for organising small items like underwear, socks, or charging cables) and detachable modular storage compartments that can be flexibly configured to accommodate mattresses of different sizes.

Design Challenge

The reliability, quietness, smoothness, and design of the pneumatic mechanism are critical to the user experience. To ensure consistent performance over time, the engineering team maintained pneumatic stroke precision within a ±2mm error margin and conducted over 50,000 open-close cycles to validate durability and reliability. Quietness is achieved through a precision damping system and low-friction hinge structures, ensuring no metallic clanks or noises during lifting, only a faint airflow sound.

The smoothness stems from an optimised air pressure release curve, eliminating the "jerkiness" common in traditional pneumatic supports, resulting in seamless motion transitions. The decision to use a manual pull handle instead of touch-sensitive or electronic button controls prioritises reliability. As a piece of furniture intended for years or even decades of use, the pneumatic system must operate consistently without external power, complex circuits, or frequent part replacements.

While electronic switches offer convenience, they carry risks of battery failure, sensor malfunctions, or circuit aging, with high maintenance costs and unpredictable lifespans that do not meet long-term engineering requirements. In contrast, the simple, mechanical pull handle is straightforward, requires no additional energy, and minimises failure risks, ensuring a consistent and predictable user experience at all times.

Sustainability

Throughout the bed board structure, no metal connectors are used for assembly except for essential fasteners required for the pneumatic mechanism. Instead, the design employs mortise-and-tenon joinery, a traditional Chinese woodworking technique, to achieve interlocking connections between components.

This method relies solely on the geometric interlocking and stress distribution of the wood, eliminating the need for screws, nails, or adhesives. It significantly enhances overall structural stability and resistance to deformation while avoiding loosening risks due to metal fatigue or corrosion.

Additionally, this detachable and non-destructive connection method facilitates maintenance and material recycling, aligning with sustainable design principles and ensuring the bed’s structural integrity and functional reliability over prolonged use.

Product Design - Homewares

This award celebrates creative and innovative design for either a component or overall product. Consideration given to aspects that relate to human usage, aesthetics, selection of components and materials, and the resolution of assembly, manufacturing and the overall function.

More Details